Go-to-Manufacturing Report

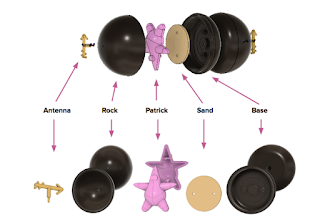

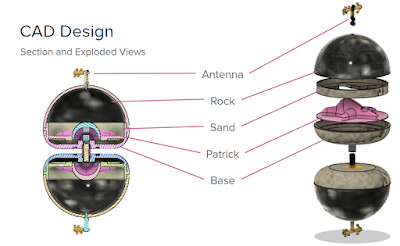

Over the past week, senior squad has been working on our go-to-manufacturing report. We used the results from our Moldflow analysis, to scale up our CAD models by about 1.2% for each part, except for the antenna which had a higher shrinkage percentage of 2.7%. We then made CAD models for the molds for our injection molded parts, and their respective CAM toolpaths.

In parallel, we worked on a bill of materials for each stock material we would need for the entire manufacturing process, and we also drafted up a layout of our factory. Here are some of the key results:

In parallel, we worked on a bill of materials for each stock material we would need for the entire manufacturing process, and we also drafted up a layout of our factory. Here are some of the key results:

Comments

Post a Comment