Final Report

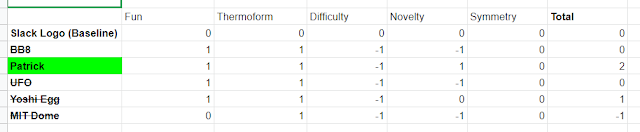

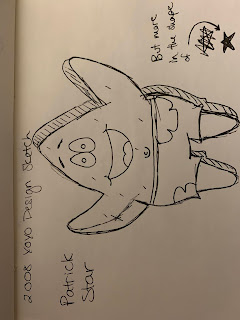

We have reached the end of the semester, and would like to update everyone with our final report! Since our go-to-manufacturing report, we have focused heavily on designing a factory using the Tecnomatix software. We have five production lines making each part. Using our agreed-upon parameters (explained in detail in the report) we were able to make 1,043,864 yo-yo's in one year! After looking at our cost analysis we would need to make around 700,000 yo-yos to break-even, and have decided to charge $10 per yo-yo to make a decent profit. However, we have strategies for reducing cost, including an infinite buffer, moving to another country with lower wages, and pursuing automation. Final Report: https://docs.google.com/document/d/1D5-LiY7y0IVv1w2rFcEP136F3LaCxJAA7q_1biwHV_Y/edit?usp=sharing Final Presentation: https://docs.google.com/presentation/d/1H7uVnHaR7ph_sm8ex6kfn2kbetREr94u9VCqMMyTe4Q/edit?usp=sharing Patrick's Final Design: Factory Layout Pro...